- Get link

- X

- Other Apps

Even if you own a full-sized tablesaw cutting a 4 8 sheet of plywood melamine or MDF into manageable-sized pieces can be a real challenge. While you can flip your plywood sheet over to make this work to your advantage with a regular blade you wont always have that ability if you need to make a cut.

Kreg Kma2685 Rip Cut Circular Saw Guide Amazon Com

Kreg Kma2685 Rip Cut Circular Saw Guide Amazon Com

You now have a circular saw guide that will allow you to rip a full length sheet of plywood.

Plywood cutting guide. Learn how to cut plywood and other large sheets down to size easily. July 14 2020. In order to cut down plywood it needs to be set up on something like a workbench or saw horses.

Firmly tighten the blade depth adjustment lever. You can get all the parts for both from a 4 x 8-ft. Setting Up Plywood Cutting Station.

But it can be challenging to make long straight cuts accurately using one. If you want to use it on the long side of a sheet of plywood cut up to half the board flip the track saw guide over and cut the rest of the plywood. Tightening the knob draws the two pieces together and because theyre beveled forces the inner block to wedge against the plywood holding the guide in place.

The inner piece is loose but attached to a knob. The outer piece is fixed to the guides arm. You can complete both in two or three hours from one sheet of MDF or plywood.

The jig can be used because of its length in both the width and length of a sheet of plywood. The factory edges on a sheet of plywood are usually straight enough to be used as a guide for cutting. The face that the teeth enter first the bottom side with a regular blade is the face that will have less tear out.

A saw guide makes it easy. The guides locking mechanism is composed of two pieces with opposing beveled sides. Yet this track saw remains a compact jig ideal for small workshops.

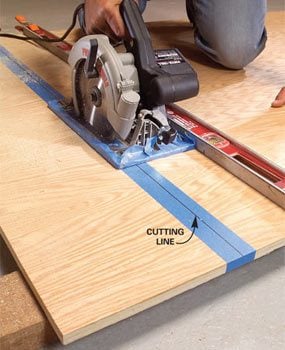

When youre cutting plywood a circular saw is a great tool to use. This type of cutting is called ripping. The Rip-Cut system uses an edge guide to give you straight cuts.

Youll always want to trim a factory edge during final sizing of a panel. Adjust the blade depth by loosening the blade depth adjustment lever on the sole the metal base of the saw and moving the sole up or down so that the blade is deeper than the base thickness of the plywood. Thats because plywood panels are difficult to move around on stationery tools like a table saw and are just simply easier to cut with a portable tool like a circular saw.

The arm is attached to the guides edge and makes it easy to cut any sheet lengthwise. Drive through the plywood first--you generally want to nail through the thinner piece into the. Before starting to cut plywood adjust the circular saw blade to the proper depth.

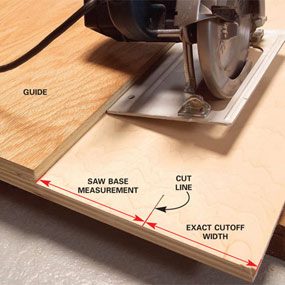

The solution is to use saw guides such as the Kreg Accu-Cut and Rip-Cut. Box nails driven every 8 to 10 in. Your cut line will be where you place the edge of the guide.

So always allow extra width for this trim cut. Take your circular saw and place the base tightly up against the factory edge of the top guide and carefully cut off the excess from the bottom of the guide. Well show you how to build the guides and make sure they produce accurate cuts.

Sliding tablesaws or industrial panel saws provide good solutions but they amount to expensive space-hogs for the small-shop woodworker who just needs to make a few cuts now and then. You can rip any length up to 24 inches using this guide. Most builders agree that the best way to cut plywood is with a circular saw.

Fasten the plywood to the 1 x 4 using wood glue and 34-in. When youre cutting plywood and other large sheets with a circular saw making long straight cuts can be challenging. But theyre generally not clean enough to be used as a finished edge.

Building the guides is a quick and easy project. A general rule of thumb is to set your saw to one tooth higher than whatever youre cutting however to keep the top and bottom layers of your plywood from splintering you can raise the saw so that its a couple of inches higher than your board and use a zero-clearance insert. Learn how to cut plywood accurately easily and safely with a circular saw.

The edge guide follows the sheets edge while the saw rides on the aluminum arm. Plywood Cutting Guide Plans. Here well show you a couple of saw guides that make cutting plywood a whole lot easier.

Please keep in mind that if you lift the saw youll have to be extra careful more of the blade will be exposed and no amount of. Build your workshop on a budget. BUT no matter where you choose to cut down your.

All you need is a circular saw and a saw guide to ensure straight clean and accurate c. Or if you prefer to cut on the ground that works too.

Plywood Cutting Guide Woodarchivist

Panel Cutting Guide Woodworking Project Woodsmith Plans

Panel Cutting Guide Woodworking Project Woodsmith Plans

Plywood Crosscut Guide Popular Woodworking Magazine

Plywood Crosscut Guide Popular Woodworking Magazine

How To Build A Simple Circular Saw Guide For Straighter Cuts

How To Build A Simple Circular Saw Guide For Straighter Cuts

Panel Cutting Guide Woodworking Project Woodsmith Plans

Panel Cutting Guide Woodworking Project Woodsmith Plans

Make Your Own Circular Saw Guide

Make Your Own Circular Saw Guide

Pin On Cutting Handling Plywood

Pin On Cutting Handling Plywood

Plywood Saw Guide Easy Diy Woodworking Projects Step By Step How To Build Wood Work

Plywood Saw Guide Easy Diy Woodworking Projects Step By Step How To Build Wood Work

Comments

Post a Comment