- Get link

- X

- Other Apps

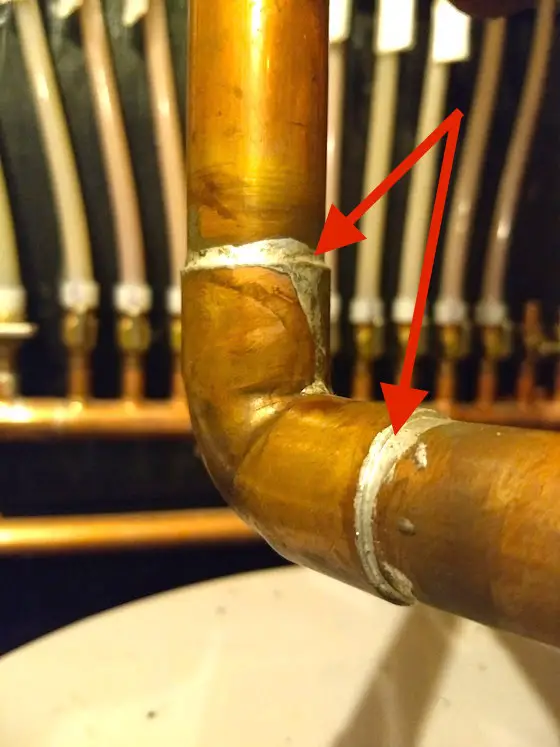

Wipe away the excess solder using a rag. Ensure that you remove dust and other debris from the internal surface of the fittings.

How To Solder Copper Pipe The Plumbers Secret Episode 1 Youtube

How To Solder Copper Pipe The Plumbers Secret Episode 1 Youtube

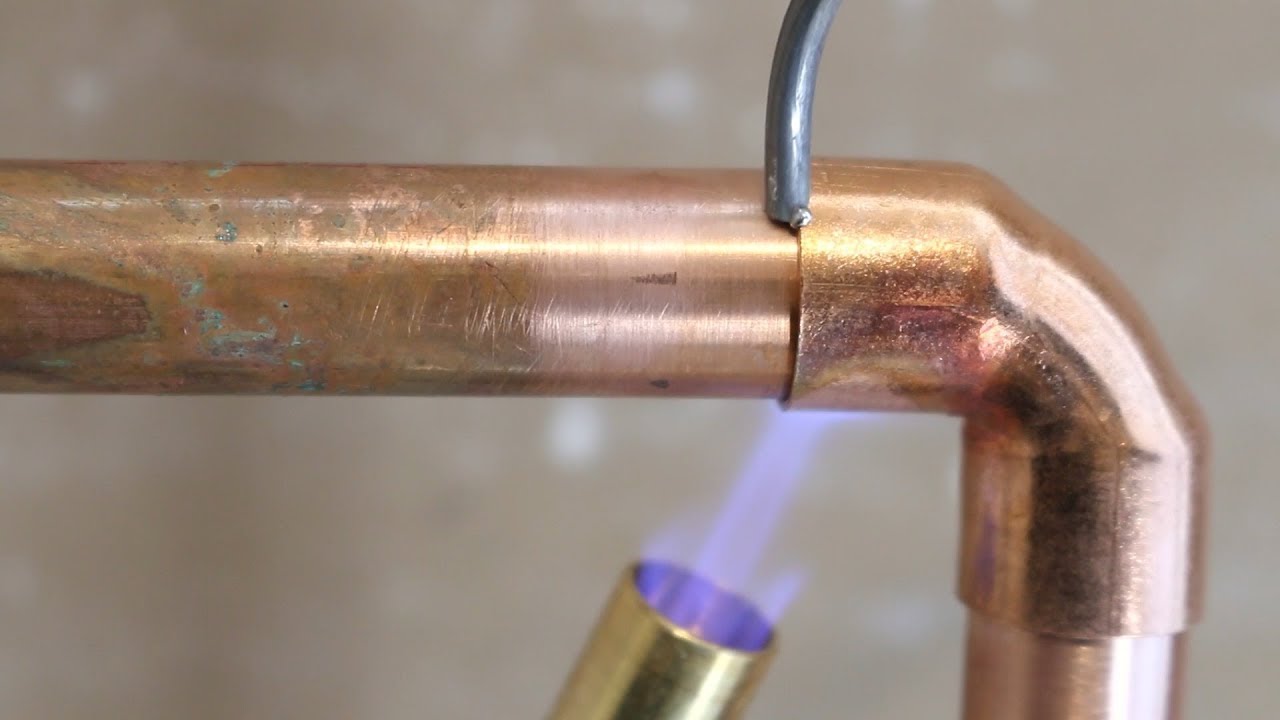

When soldering copper pipe first touch the solder wire to the tube.

Solder for copper pipe. Having the right soldering flux will ensure the copper pipe are strongly soldered. How to Solder Old Copper Pipe. It is used in covering the cleaned copper surfaces to be soldered before heating and assembly.

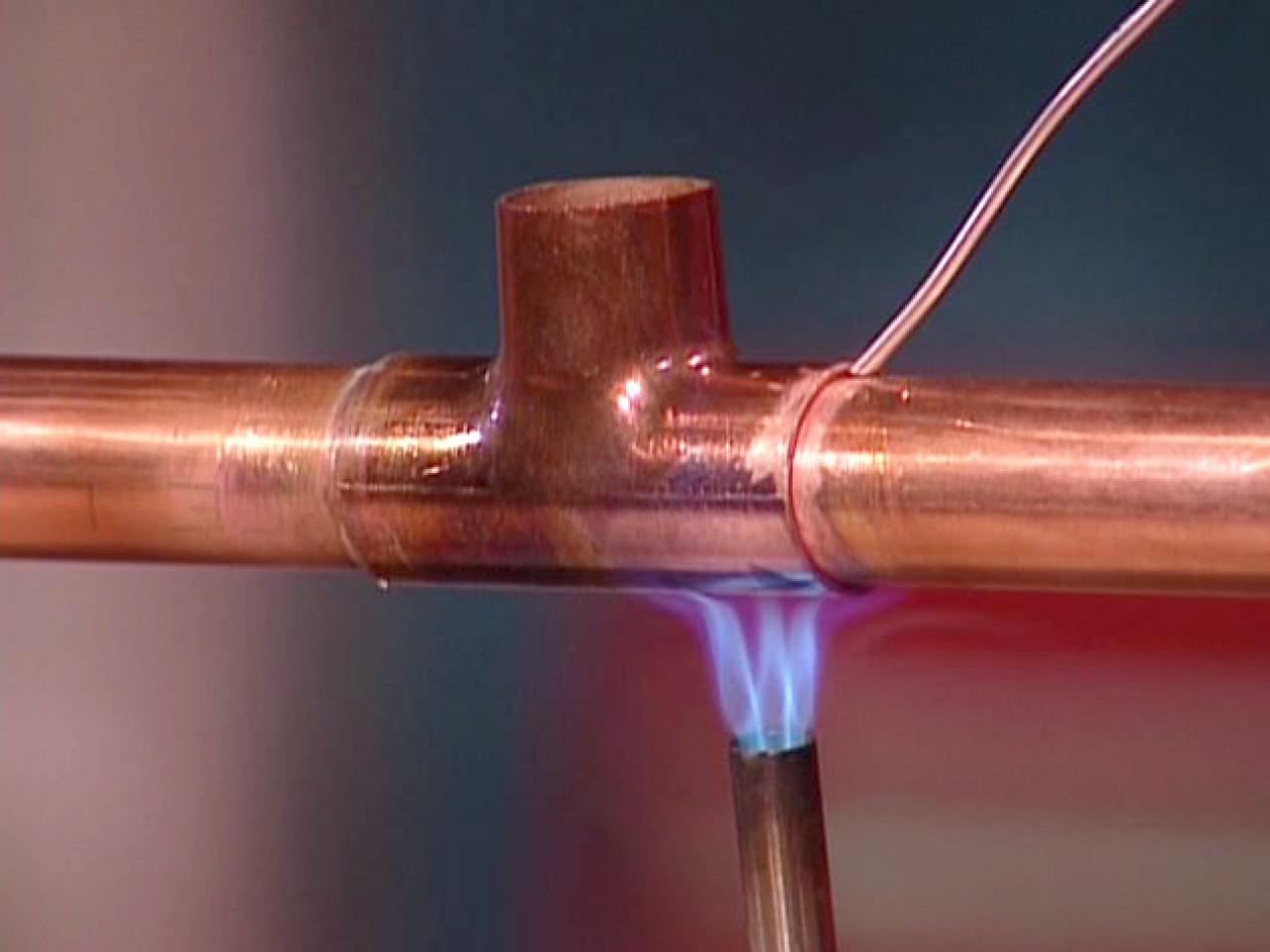

Although soldering copper pipes might sound straightforward due to the safety risks involved its always advised to hire a qualified professional to undertake these works. With the right tools information and a touch of patience you can avoid the worst soldering copper pipe problems. Insert ½- to ¾-in.

Soldering the old copper pipes will require the removal of dirt and the corrosive layer on them. The most common DIY soldering for copper pipes is on a water pipe which is why some delicacy is required. Soldering copper pipe requires a relatively large amount of high intensity heat which is why a propane torch is typically used to heat the joint.

Cost to hire a professional You can expect to pay a plumbers hourly rate which is an average of 20 40 per hour. Flux is generally a jelly containing zinc chloride or sometimes jelly with rosin cleaning components. Of solder into the joint.

Using a wire brush you have to clean the inner surface of each fitting. Lead free solder is best for copper pipes carrying drinking water. A paste-like solution using white vinegar baking soda and salt should be prepared taking equal parts of each should be prepared.

However it will require a higher melting point than a 5050 solder. The heat should be applied as evenly as possible around the fitting. Step 7 Remove the flame.

Step 8 Clean the fitting. After the fitting and tube have cooled install the pipe turn on the water and. Cost to do it yourself.

Ad Find China Manufacturers Of Solder. The amount of heat needing to be applied will vary but well deal with that in the next step. You cant use a soldering iron here.

Ad Find China Manufacturers Of Solder. Copper Pipe Soldering-How to Solder for Beginners Video - YouTube. Step by Step Process of Soldering Copper Pipes.

You want a potable water supply and not something which has been contaminated by flux solder or anything else. Below is the step by step process on how you should correctly solder copper pipes Step 1. What Type of Solder is Used for Copper Pipe.

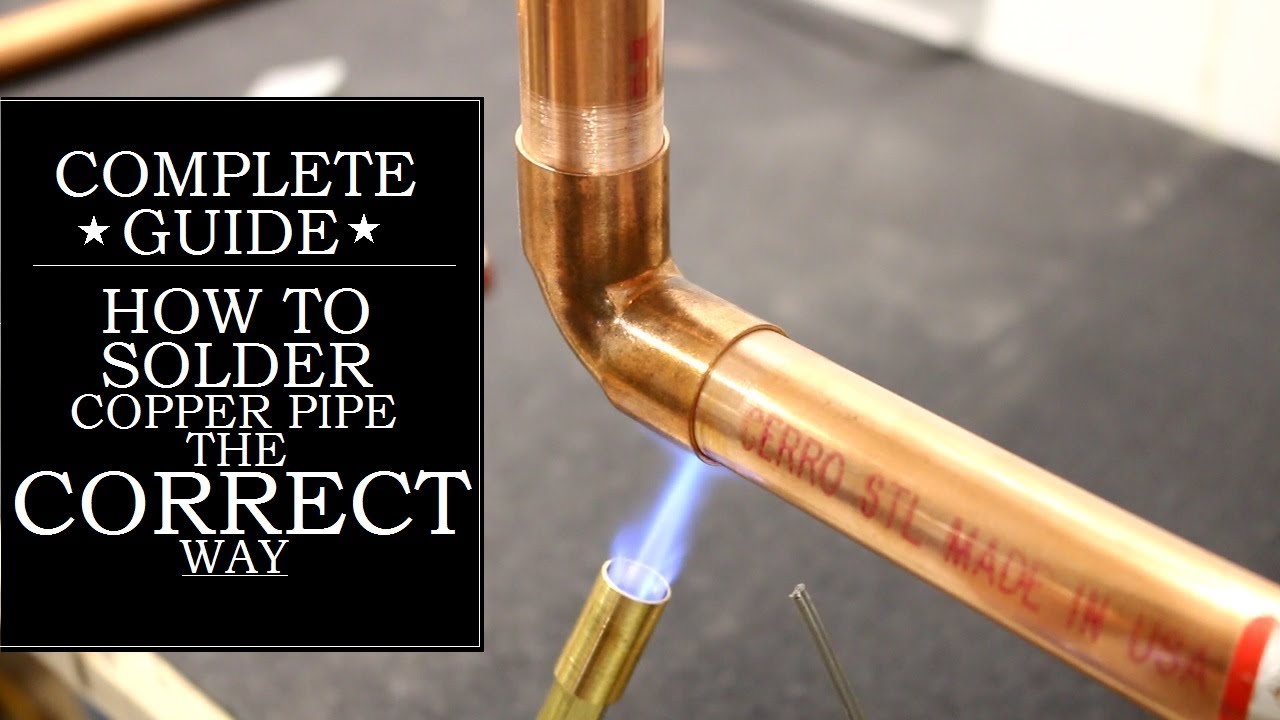

If the solder melts the tube is ready for soldering. Soldering Flux for Copper Pipes Soldering. This video will explain to you in details how to solder copper the CORRECT way so you can do it yourself and not have to pay an expensive plumber and save TO.

Clean and Smoothen the Inside of Fitting. But not too hot or youll burn the flux and oxidize the copper at which point you need to. It will be free of elements you dont want entering your drinking water.

Then it is to be applied to the corroded areas of the pipes. Hot enough to melt solder the pipe never apply the flame directly to the solder - apply the flame to the joint and the solder to the joint away from the direct flame. When it starts to smear its close.

/Soldercopperpipe-GettyImages-157186637-597579fec4124400114f2c5f.jpg) Tools Needed For Soldering Copper Pipe

Tools Needed For Soldering Copper Pipe

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe How Tos Diy

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Solder Copper Pipe Sweat Copper Pipe Bernzomatic

Comments

Post a Comment