- Get link

- X

- Other Apps

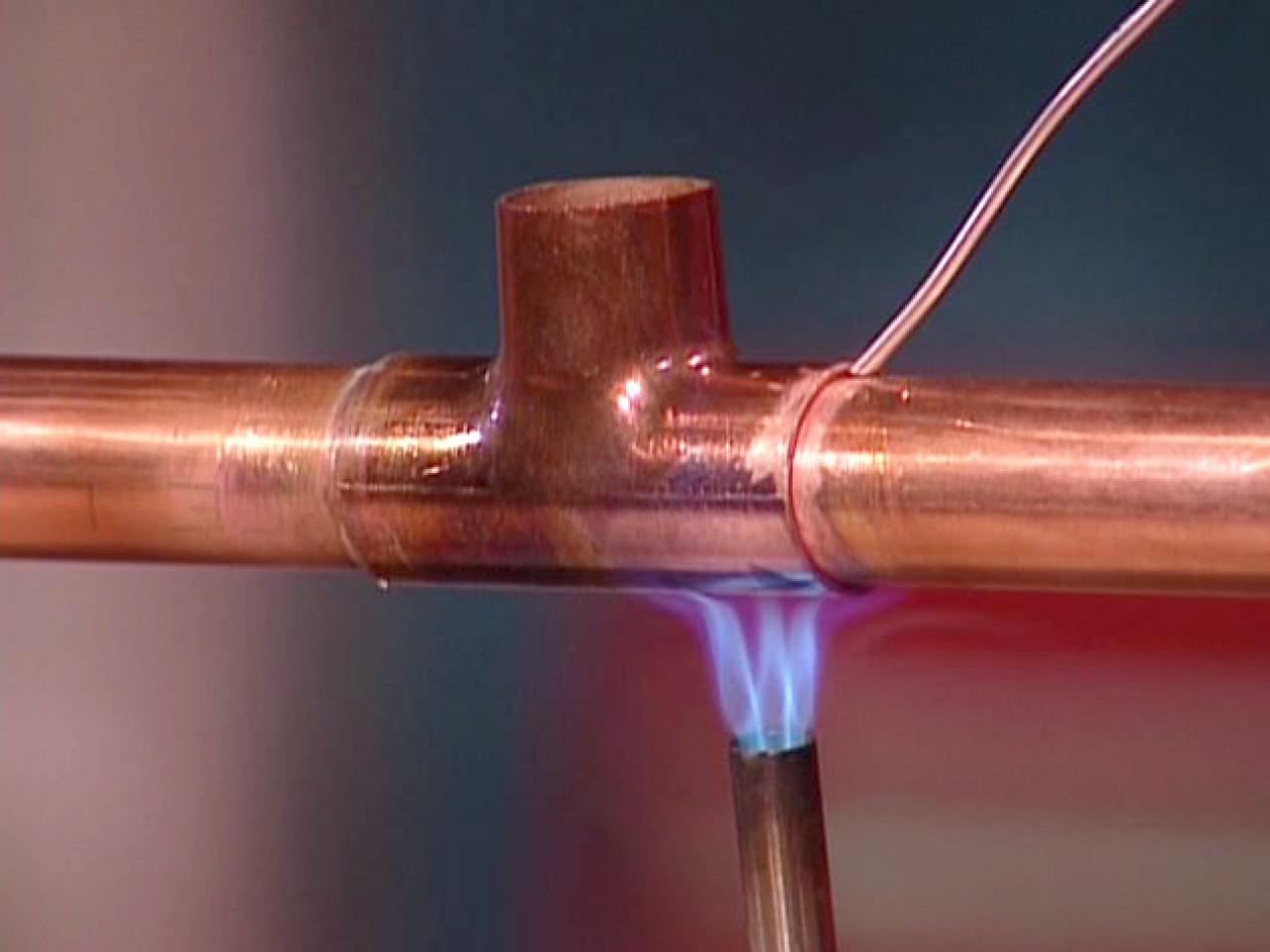

If there was a leak youd have a lot of water exiting and making a large mess. To join copper pipes together it helps to add a paste called flux to the ends.

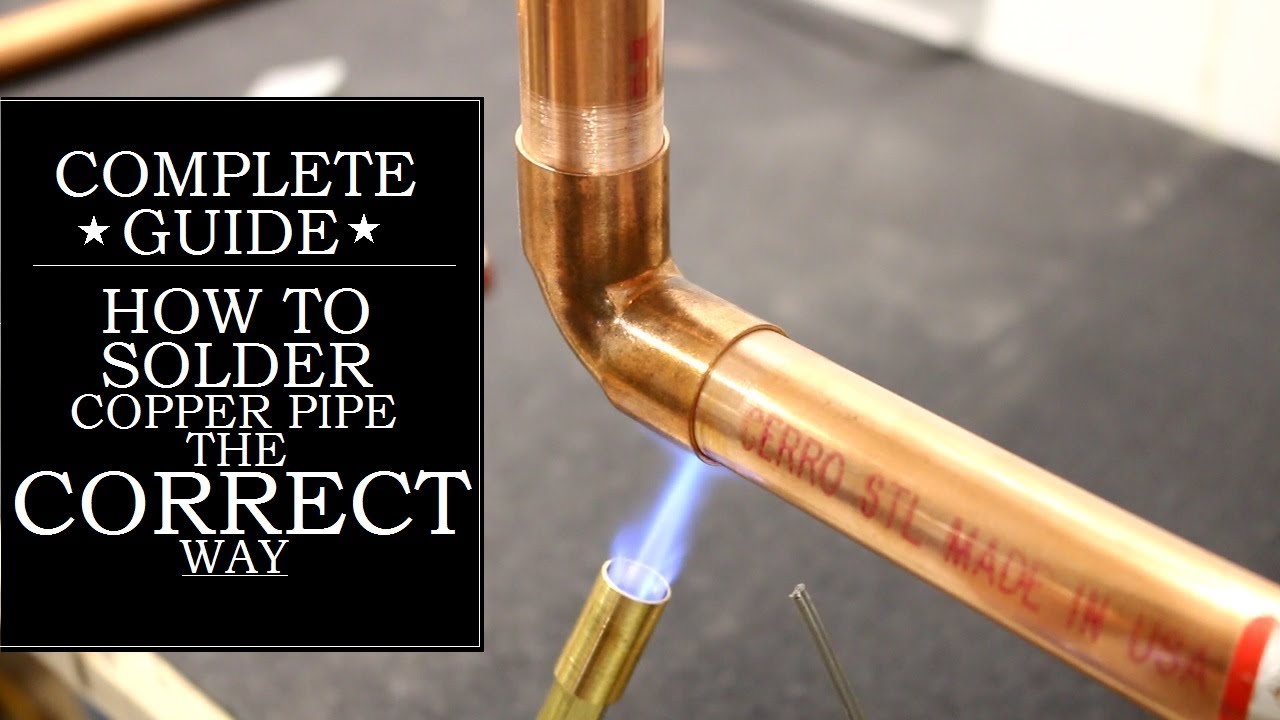

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

The solder will flow into all areas of a properly cleaned and fluxed.

Soldering water pipes. The metal on either side of the joint isnt melted like in welding but the solder is. Apply a nice coating of flux to both pieces and slide together. Soldering pronounced soddering or saw-ter-ing is a way of joining pipe using solder.

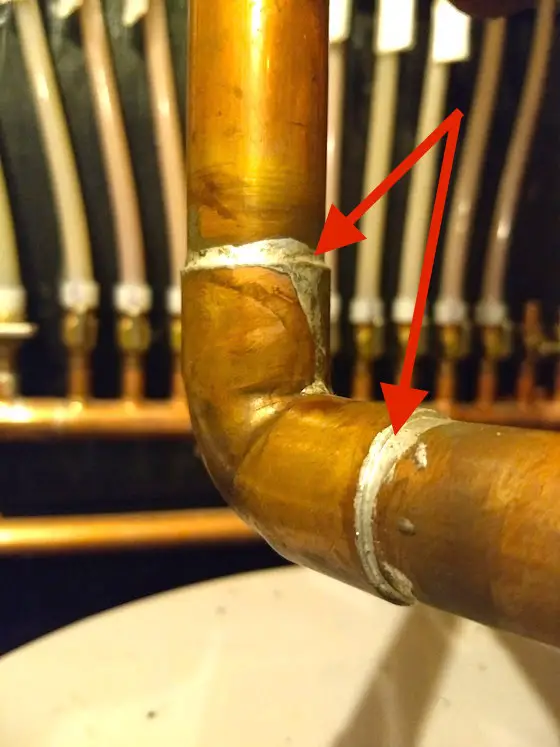

Therefore you have to stop the water flow temporarily. The old pipes are green oxidation but I clean the joints with wire brush. If you do not see that on the label exercise caution and use a different soldering material for your drinking water pipes.

The label should clearly state that the solder is safe for drinking water. You can also DIY the plug using paste-like materials such as. The Soldering process needs to be carried out when the pipe is dry.

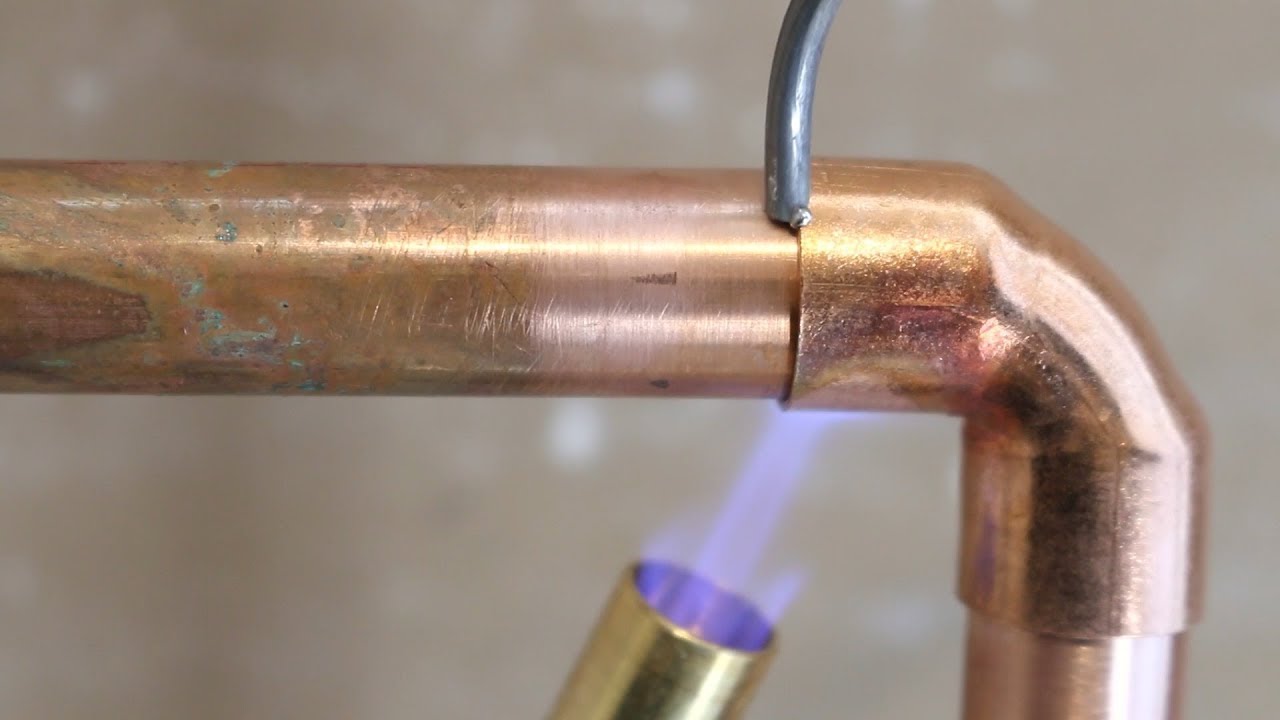

When the copper is hot enough the solder will melt like butter. Place the device torch on the soldering area for about 5-6 seconds for the solder to spread evenly. Test the joint by touching the solder to the seam on the side opposite the flame.

Fittings are brand new. For even distribution of heat and solder repeat the above-mentioned procedure to the opposite part of the copper pipe. Of solder into the joint.

In order to join pipes together its necessary to solder the joints together so they dont leak water. You can buy a pipe plug off the market or create your own dampener. The water pressure inside a typical house should be between 40 psi and 80 psi.

Benzomatic lead free plumbing water soluble plumbing flux. To start soldering lit the propane device torch and direct its tip to the area you want to solder. Here are 7 solutions to soldering a copper pipe that has water flowing thru it-----.

A lot of us plumbers use end feed fittings and solder them with leaded solder wire on heating pipes as it is easier to solder and cheaper but unleaded solder must be used for potable water joints To solder well you need to have the pipe and fittings clean and keep the joint well fluxed while applying heat from torch. Solder is a filler metal that goes into the joint between two pieces of pipe. Move the flame away from the joint and feed about 12 in.

Unroll about 12 of solder from the roll and bend the end to form a hook shape leaving about 10 between you and the end. My first solder attempt a year ago was successful main difference is indoor vs outdoor. Yes Im heating the pipe joint and trying to apply solder on opposite side of heat.

If you plan on repairing a pipe that contains drinking water you will need to select solder material that does not have lead. Soldering Water Heater Pipes in 8 Steps Now that youve got a clean pipe and fitting youre ready to get to work.

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

How To Solder Copper Pipe Joints For Water Or Another Liquid

How To Solder Copper Pipe Joints For Water Or Another Liquid

Why Don T We Use Soldering Instead Of A Pipe Thread Sealant Quora

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Correctly Solder A Copper Pipe 6 Steps With Pictures Instructables

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

How To Solder Copper Pipe In A Wall Complete Guide Got2learn Youtube

How To Solder Copper Pipe Sweat Copper Pipe Bernzomatic

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Solder Copper Pipe The Correct Way Got2learn Youtube

/Soldercopperpipe-GettyImages-157186637-597579fec4124400114f2c5f.jpg) Tools Needed For Soldering Copper Pipe

Tools Needed For Soldering Copper Pipe

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

Comments

Post a Comment